There’s a lot more to making concrete than meets the eye. Ever wondered what the process of curing means? It’s an essential part of the process of making strong, durable concrete but what does it involve and why does it need to occur?

When you add water to cement, a chemical reaction begins called hydration. Over time, this process of hydration changes the cement and water into calcium silicate hydrate compounds. This is a fancy name for the glue that makes the cement stick together. It becomes the binding agent, holding the aggregate together and forming the tough, solid substance that we rely on for our roads, pavements and buildings. Other compounds also form during this hydration process, but they do not make the cement stronger like the calcium silicate compounds.

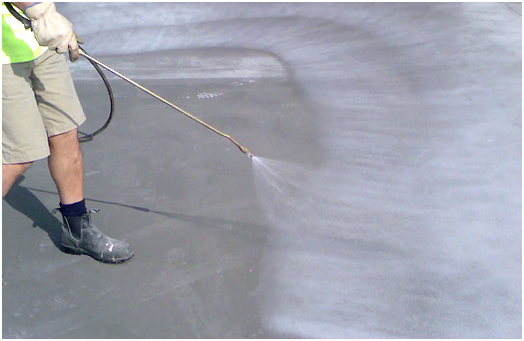

Curing is needed to maintain this vital process of hydration. It maintains the moisture levels deep inside the concrete to let the hydration process continue. You wouldn’t imagine so much was happening after concrete had been laid! If moisture and unhydrated cement are present inside the concrete, it will continue to harden, get stronger and denser. In a nutshell, curing is the method of keeping cast concrete moist, so the process of hydration can continue. For Concrete Pumping Gloucestershire, visit http://www.monstermixconcrete.co.uk/concrete-services.php

As the concrete continues to hydrate, its porosity declines as it gets stronger. The reason this is important is that newly laid concrete is much more porous than older concrete, which has had longer to hydrate. The higher the porosity of new concrete, the more moisture evaporates from its surface. This lowers the moisture levels inside that are so vital for hydration to continue. If your concrete dries out too quickly, it will not be as strong. That is why you should never cover over freshly cast concrete.

Concrete is not fully cured until most of the cement has been hydrated. This can actually take months, or even years! Normally, concrete is cured just long enough for it to reach its desired strength. Therefore, the time for curing depends greatly on the purpose of the concrete. The temperature, mix design and required strength are all factors to be decided when embarking on construction with concrete.

Concrete that is needed quicker will have its mix design tailored to reflect this need. After all, customers are not going to want to for months for their delivery! Mix designs have been tailored to have early high strengths, enabling the concrete to be cast, cured, processed and out for delivery in a matter of days. Construction grade concrete is designed to achieve very high levels of strength in under a month. Advanced mixes can achieve desired strength in just a few hours if necessary.

Temperature also has a significant impact on curing times. Cold temperatures mean strength levels are achieved much slower than in warm conditions. Strength is vital in concrete as it is used to build some of our most important infrastructure. Weak concrete is dangerous as it can crack, soften or chip.