Metal coatings are a way to protect a surface to improve its resilience and reduce the risk of corrosion. Depending on the type of metal and its purpose, which form of coating is most appropriate varies. Here are some common kinds.

Paint Coating

As the name suggests, a layer of liquid paint is used. It is a less durable method, but it is also quicker and more cost-effective. Some paints contain dangerous toxins.

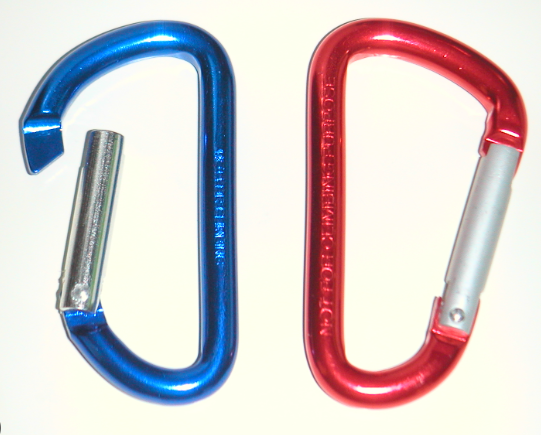

Powder Coating

Powder is applied through an electrostatic method to create a durable and aesthetically pleasing coat. It can save money in the long term, but short-term costs are higher. Thin coats are very difficult.

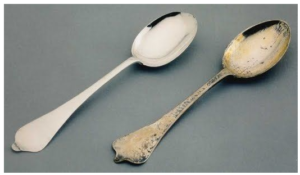

Electroplating

A layer of metal is attached to the surface with the help of an electrolytic solution and an electric current. This can enhance the properties of the surface metal. It is aesthetically pleasing, but the coat is not always evenly spread (electroless plating is an alternative).

Galvanising

Iron or steel is submerged in molten zinc and then removed to cause a reaction with carbon dioxide and oxygen in the air. This creates a stable, durable, protective zinc sulphide coating. Unfortunately, this is expensive, and the resulting surface can look dull and unpleasant.

This is most effective with aluminium and is not suitable for all metals. Surfaces are placed in an electrolytic solution with a cathode. An electric current oxidises the aluminium. The coating is stable, non-toxic and easy to maintain.

Thermal Spray

Thermal spray uses heat to apply an extra thick coating. It may be a thermal plasma spray, as can be seen at poeton.co.uk/advanced-treatments/apticote-800-thermal-plasma-spray/, or a wire arc spray.

When you have a metal surface that needs coating, you need to consider all the available options to choose the most suitable one for your needs.