In order to get a good fastening and a joint that without significant force will not pull out a screw or a nail, construction professionals do not drill – they tap. They use devices to provide an additional degree of protection to the joints and fixings.

Screws and bolts allow a good link between materials using a thread. But by drilling, a thread is not formed. This stems from tapping. For a drill, a tapping system uses rather a different operation. With smooth sides, drilling produces a vacuum. A tapping machine uses an action on the side of the hole which creates a thread.

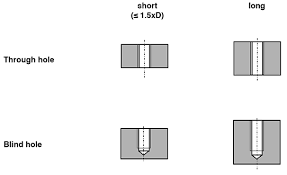

A thread to the bottom of a hole is cut by bottom tapping devices. In materials which are prone to cracking, taper taps progressively build a hole with a thread. In holes that go through a material, plug taps add threads. For general-purpose programmes, hand taps are. For deep hole tapping, spiral pointed taps are effective because they push material forward into the hole thanks to placing threads at those threads.

It is not surprising, with so many different types of taps, that different taps need to be used for different materials and with every project. Factors such as a hole’s width and depth or whether it goes through a material affect the option of what kind of tap should be applied.

Suppliers of tapping machines such as Cotswold Machinery Sales use pneumatic force and swivel arms for many tapping jobs to give adaptable speed. Machines that can fit in and be used in smaller rooms provide versatility and improve investment returns. Also many versions are compact. They are able to discuss the best options with you for relevant tapping machines based on your personal requirements.